Flame Arrester

- Home

- >

- Flame Arrester

Performance Driven

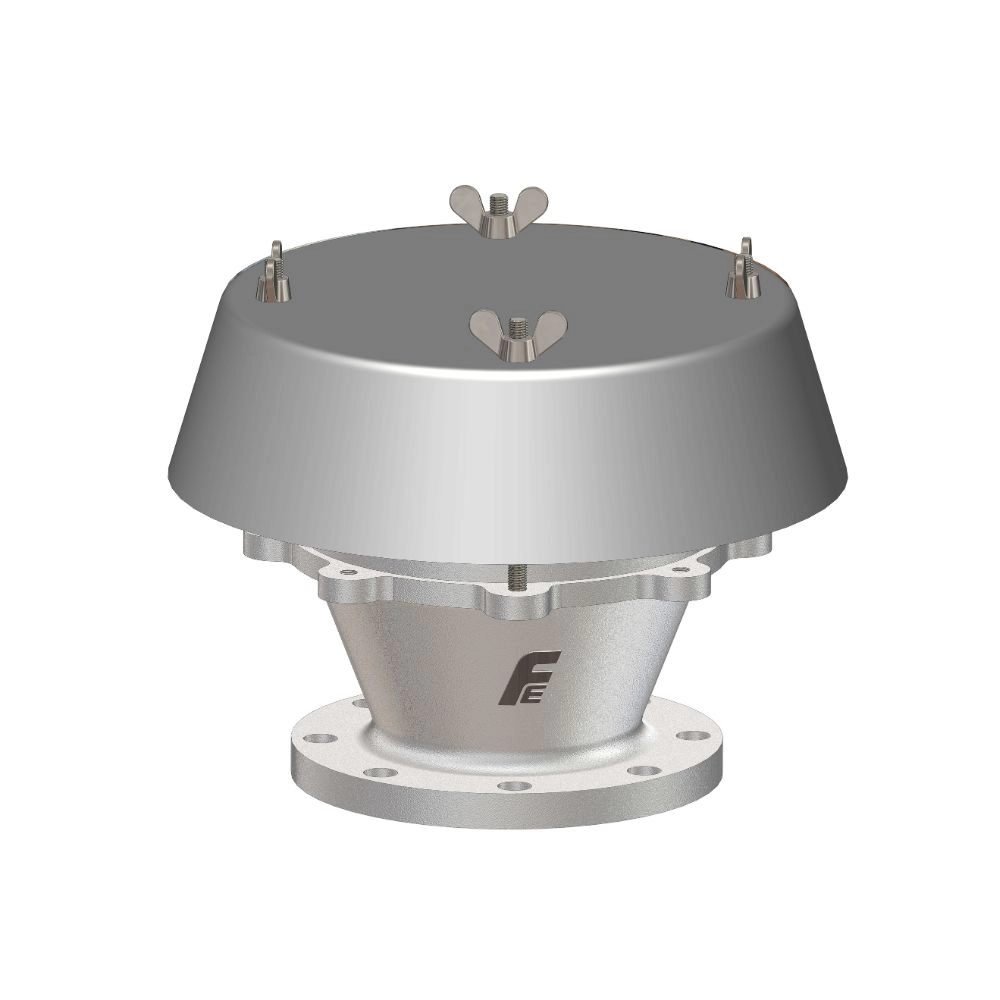

About the Product

Flame arresters are passive, mechanical devices installed on a storage tank nozzle or in a vapor piping system. Its primary function is to allow gases to pass through during normal operating conditions, but stop a flame in order to prevent an explosion or fire propagation under emergency situations. Stopping the flame protects the storage tank, or the equipment located in the piping system, from the catastrophic damage that may result from an uncontrolled ignition. For industries that handle, store, transfer and collect hazardous liquids, a single unchecked flame can cause extensive damage to both plant and equipment, not to mention the risk of personal injury or loss of life.

A variety of arrester designs are available. The selection of the appropriate arrester depends on the flammable properties of the vapor/air mixture, operating conditions as well as how and where the arrester is installed with respect to the potential ignition source. Shown below are three primary categories of arresters that are available in the market. The user must be assured that the arrester selected has been tested for conditions that match or exceed the intended application. Fainger flame and detonation arresters are developed in accordance to the testing / listing criteria of nationally recognized independent agencies such as Underwriters Laboratories, Inc. (UL), Factory Mutual Research (FM) and the United States Coast Guard (USCG). Also available are models that are type approved according to the latest ATEX Directive and ISO 16852.

A flame arrester is a passive device that allows gas to pass through it but stops the propagation of a flame.

Stopping the flame protects the storage tank, or the equipment located in the piping system, from the catastrophic damage that may result from an uncontrolled ignition. For industries that handle, store, transfer and collect hazardous liquids, a single unchecked flame can cause extensive damage to both plant and equipment, not to mention the risk of personal injury or loss of life.

The selection of the appropriate arrester depends on the flammable properties of the vapor/air mixture, operating conditions as well as how and where the arrester is installed with respect to the potential ignition source.

Flame arresters fall into two major categories:

In-Line : to prevent the propagation of an explosion within a pipeline.

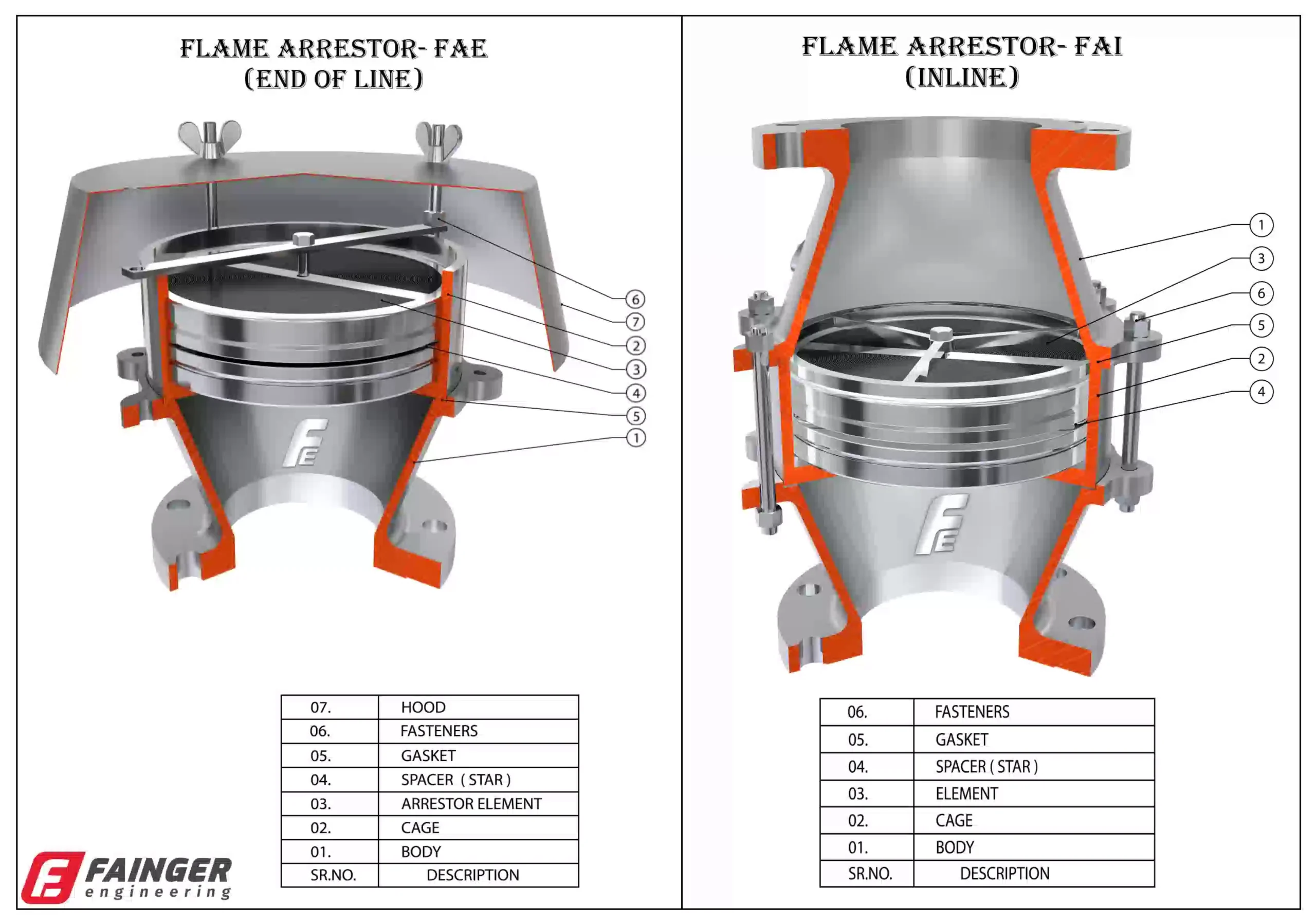

End of Line – Deflagration Flame Arrester:

End of line arrestor are designed to prevent the travel of the external flame caused by an external source of ignition from entering a system and also sometimes to prevent the flash back of a flame which has been stabilized on the arrestor. These are mounted at the end of a pipe (flanged or threaded inlet connection) and vents directly to the atmosphere.

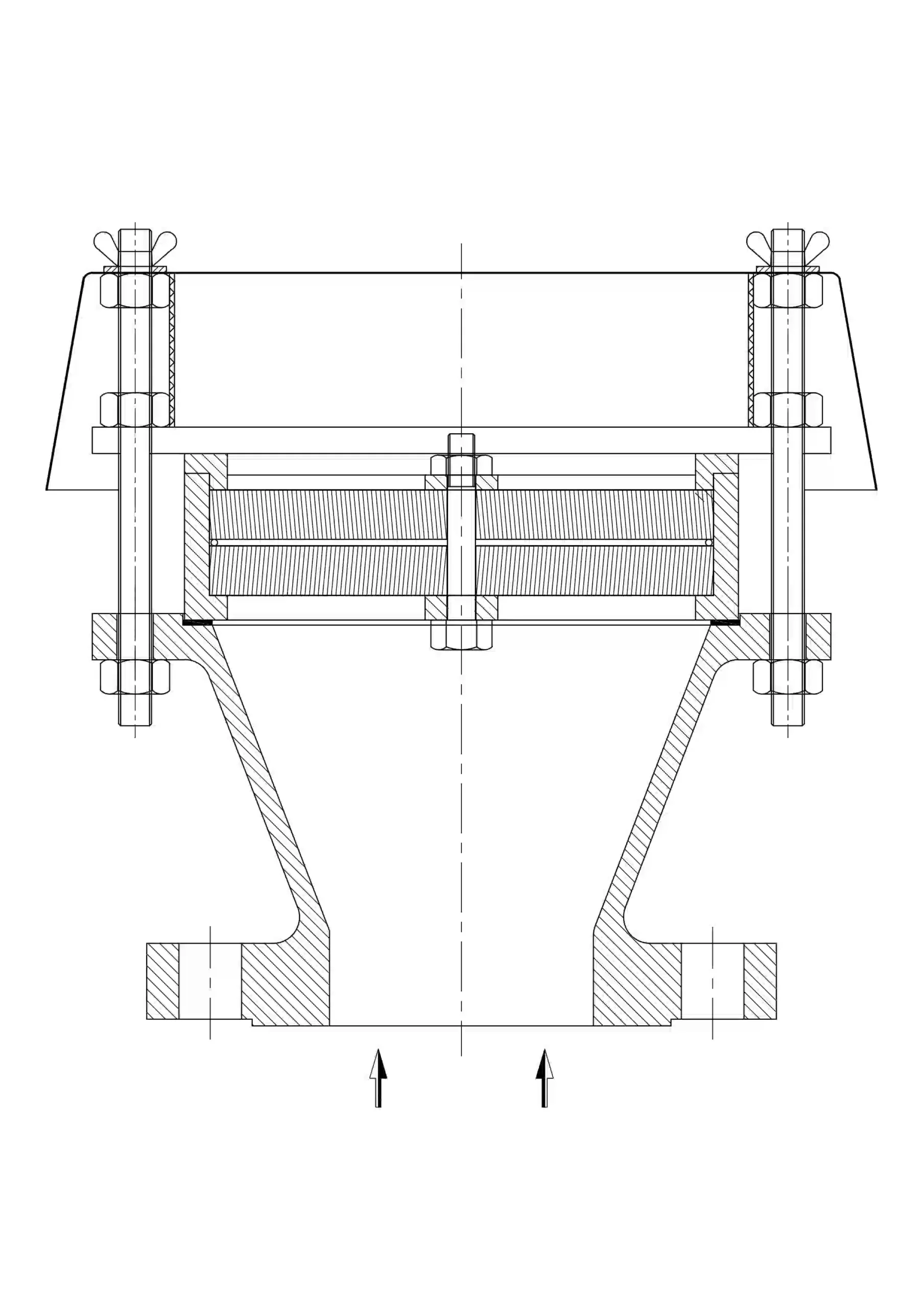

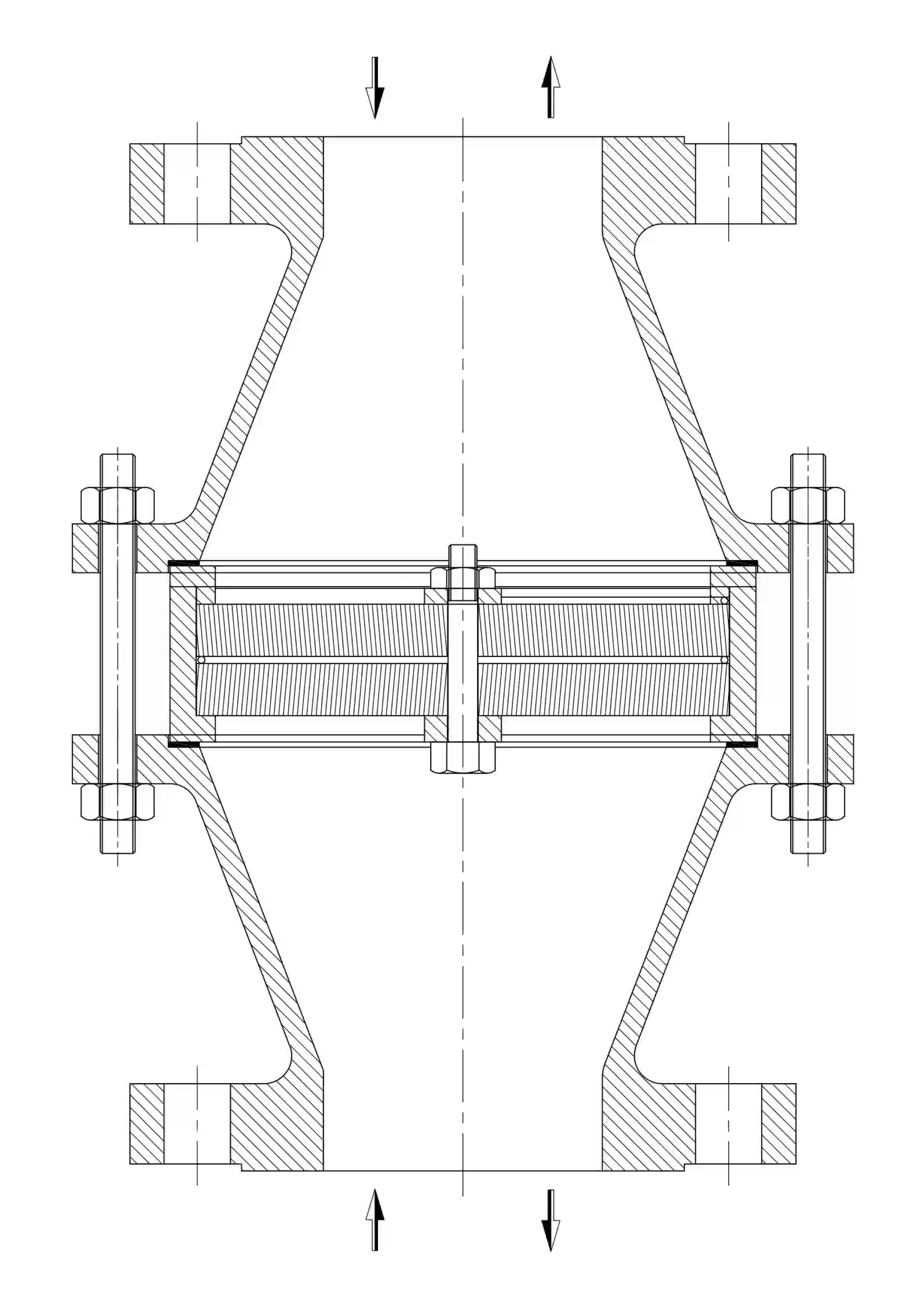

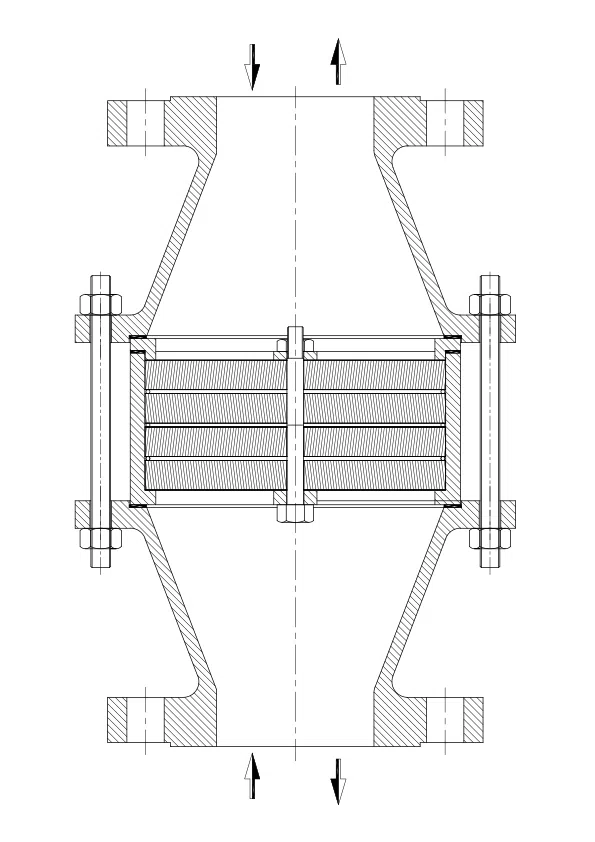

In-line Deflagration Flame arrester:

They prevent flash back against deflagrations in a pipeline. Therefore, it is usually recommended that the flame arrestor be located as close to the potential source of ignition as possible. The maximum distance from the potential source of ignition will always be defined for any in-line deflagration flame arrestor and will be typically within 20 x the nominal bore of the pipe in which the arrestor is installed. If compliance with this constraint is not possible then it will be necessary to install a detonation flame arrestor which will withstand the more severe conditions that could occur.

In-line Detonation Flame arrester :

Detonation Flame Arresters are designed to be installed in a pipeline where there is a significant distance between the arrestor and the potential source of ignition, or where the pipeline contains multiple bends, elbows and other changes of direction, all of which create turbulence and increase flame front speed. In-line detonation Flame Arrester offers protection against high flame velocities, where the velocity is supersonic and is accompanied by a shock wave.

Detonation arrestors must be especially applied when long pipes are connected between arrestor and ignition source.

Features

- Gas group : IIA, IIB & IIC

- Size Range: from ¼” to 24”

- Gap sizes range from 0.2 to 0.9 mm

- Wide range of material combinations available

- Tested as per IS 16485 std. from CIMFR-Dhanbad

- Low Pressure drop due to crimped metal ribbon design Arrester Elements

- Maintenance friendly Multi-layer arrestor elements for easy removal & cleaning

Let's start your project to be realize.

Our skilled team ensures that each valve meets stringent quality standards, offering durability and optimal performance. Explore our range of products and discover why we are a trusted name in valve manufacturing.