End of Line Breather Valve and Flame Arrester

- Home

- >

- End of Line Breather Valve and Flame Arrester

Performance Driven

About the Product

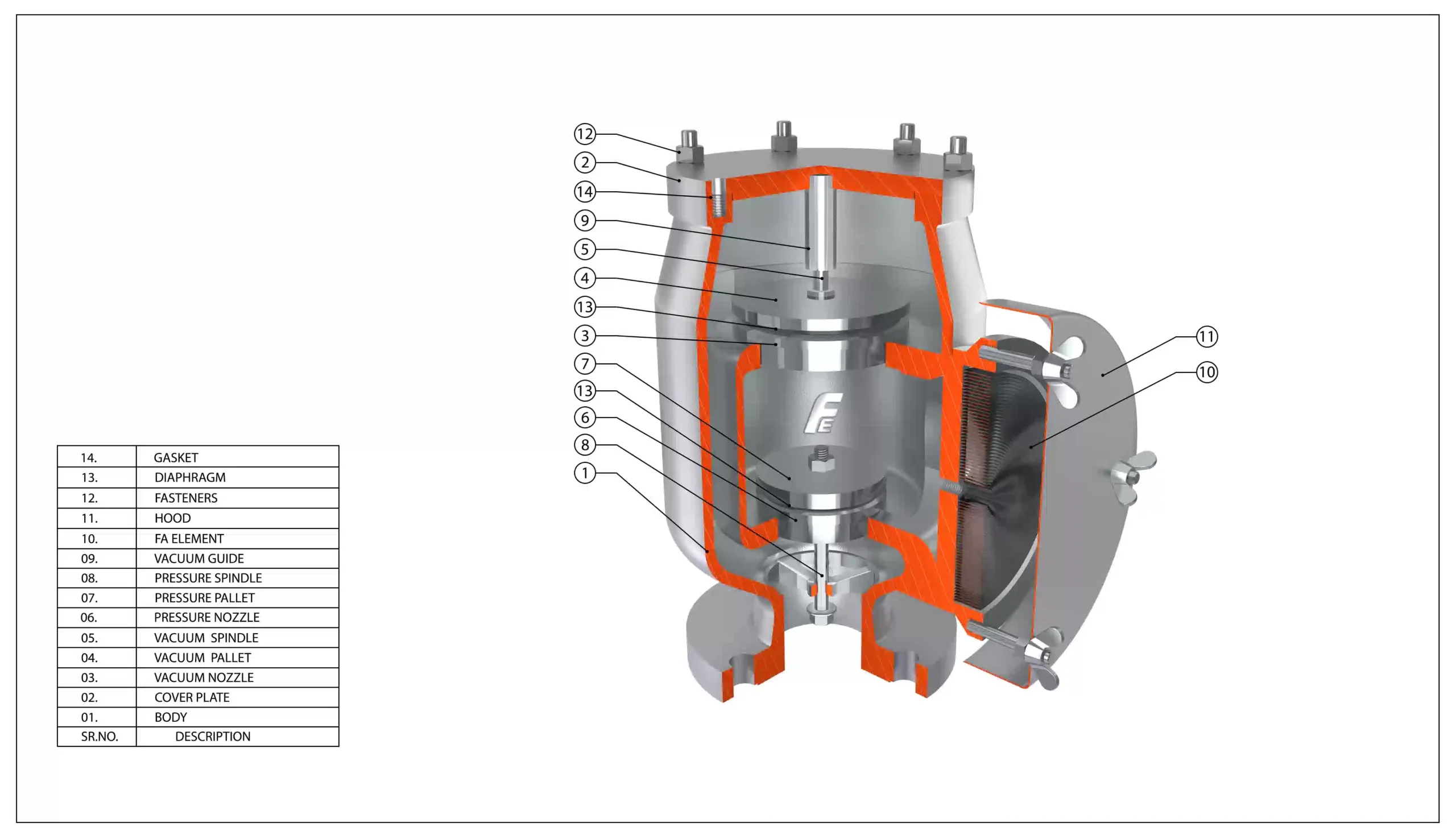

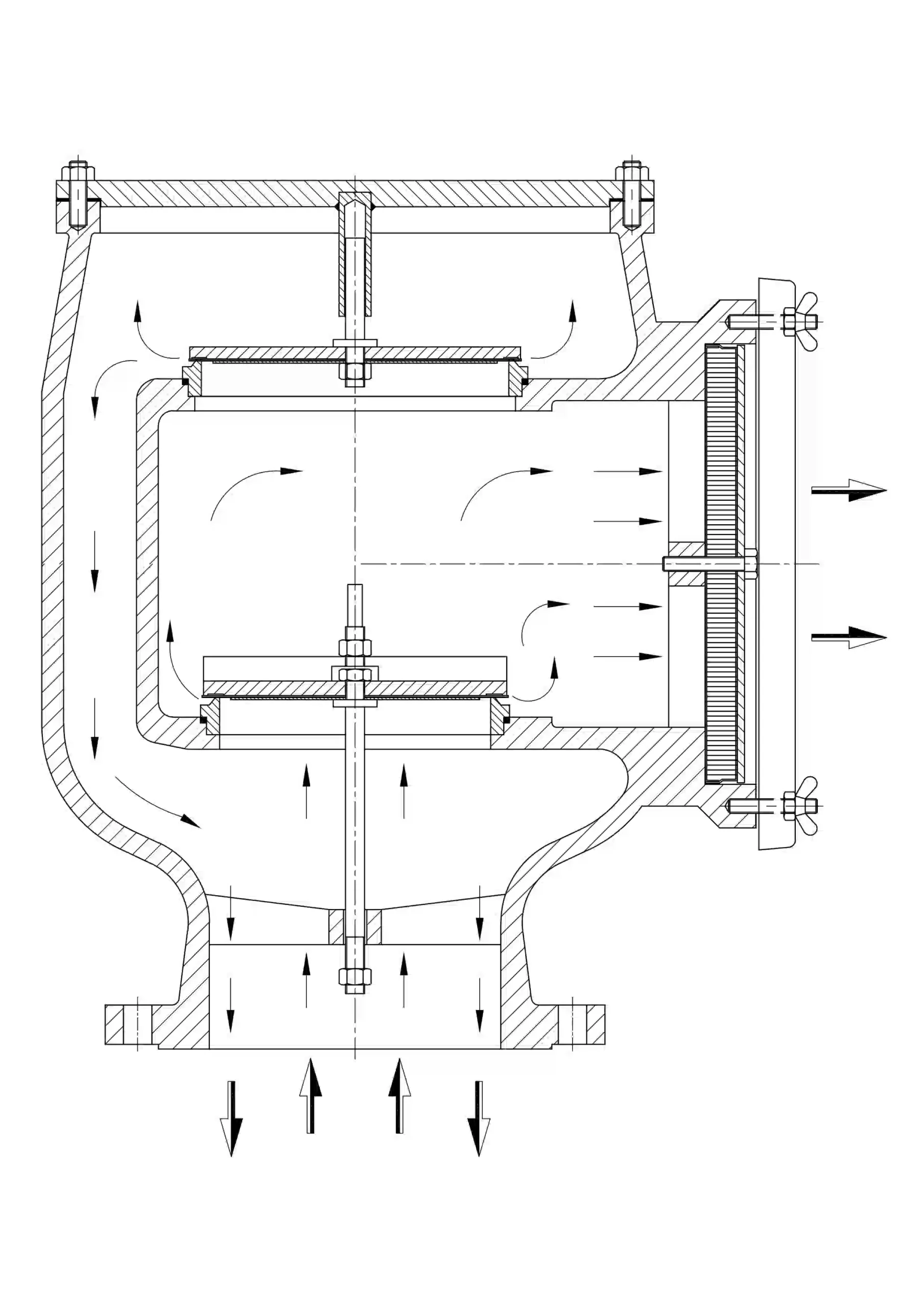

The Fainger make Pressure / Vacuum Relief Valve with Flame Arrester is designed to prevent costly evaporation losses, tank rupture due to over-pressure, and collapse due to vacuum. The flame arrester protects tank against fire and explosion caused by exterior sources of ignition. Pallets in the vent housing minimize air and vapor loss as the tank “breathes”. They open and close just enough to maintain safe working pressures and avoid damage to the tank. The flame arrester element is mounted externally and is only exposed to vapors when venting.

Features

- Certified test report verifying specified settings and leakage performance

- “Air-cushion” pallet design for low leakage performance

- Flame Arrester provides protection against atmospheric deflagration

- Flame Arrester integrated into the valve saves space and reduces cost

- Removable and interchangeable element(s) facilitates easy inspection and maintenance

- Unit is serialized for easy identification

- Automatic condensate drainage design

Specifications

- Sizes: 1.5” (DN 40) through 10” (DN 250)

- Connections: ANSI 150# as Standard.(Other Flange Std available on request)

- Materials: Carbon Steel, Stainless Steel

- Gas Groups: IIA/B

- Standard Setting Range*: Pressure: 20 – 500 mmWC

- Standard Setting Range*: Vacuum: 20 – 500 mmWC

Options

- Diaphragm Materials: PTFE, Viton, Buna N, EPDM and Neoprene; other materials available upon request

- Materials certifications for castings/Trim Parts

Let's start your project to be realize.

Our skilled team ensures that each valve meets stringent quality standards, offering durability and optimal performance. Explore our range of products and discover why we are a trusted name in valve manufacturing.