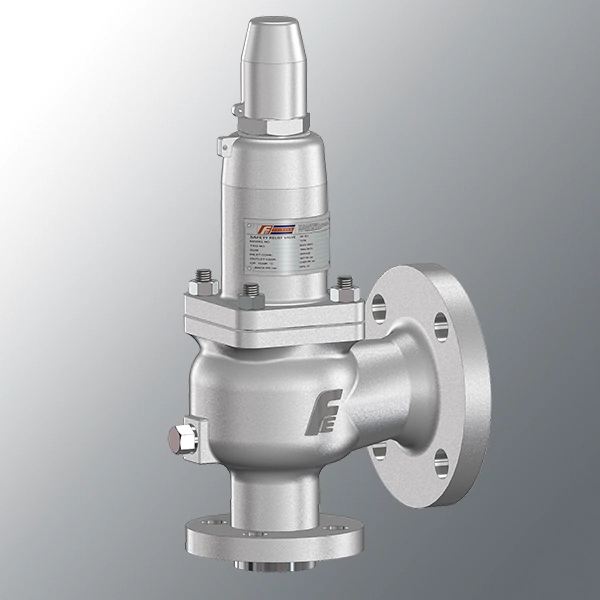

Safety Relief Valve

- Home

- >

- Safety Relief Valve

Performance Driven

About the Product

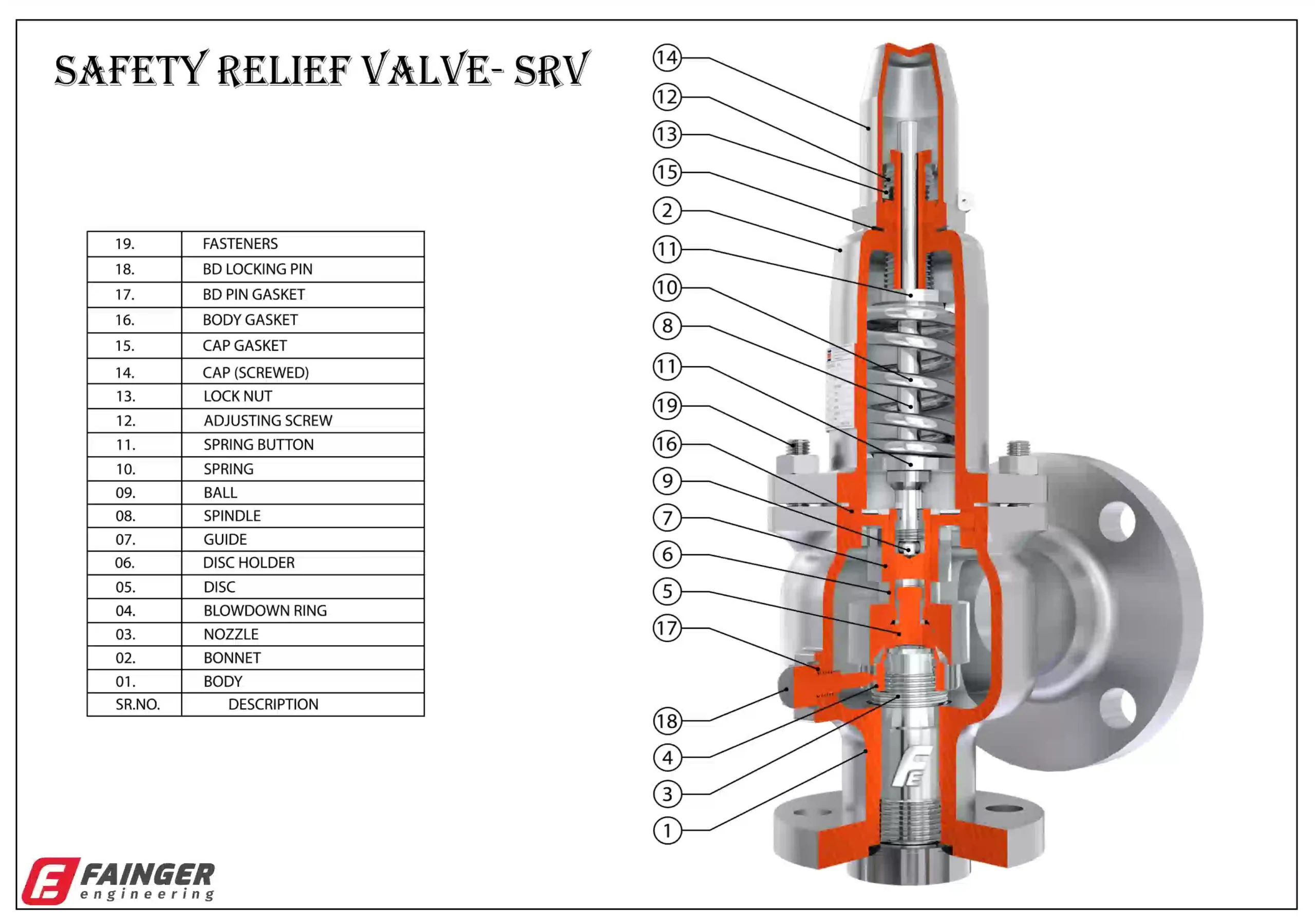

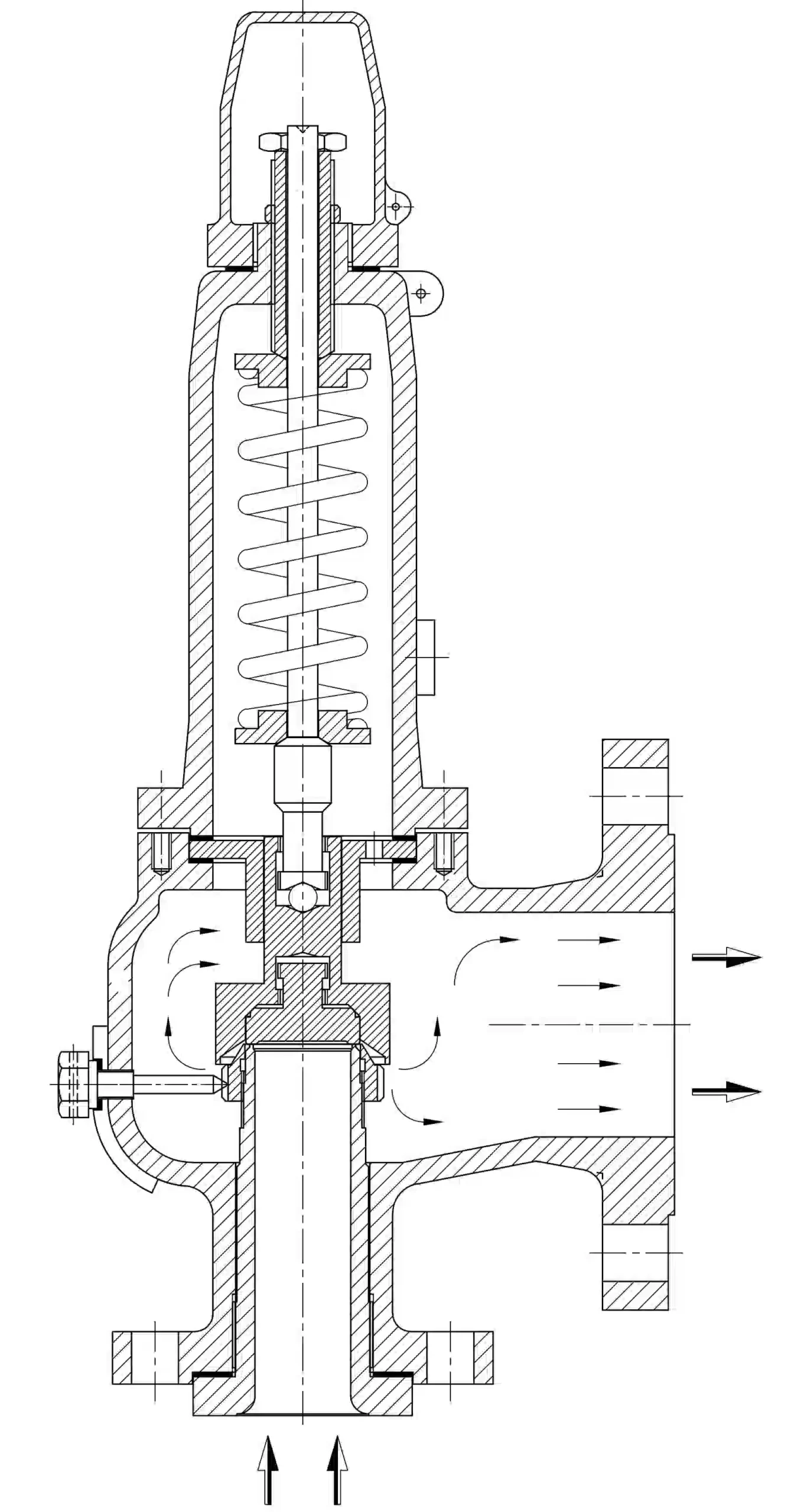

The Fainger make safety valve is designed to open and relieve excess pressure from vessels or equipment and to reclose and prevent the further release of fluid after normal conditions have been restored. The primary purpose of a safety valve is protection of life, property and environment.

A safety valve is a safety device and in many cases the last line of defense. It is important to ensure that the safety valve is capable to operate at all times and under all circumstances. A safety valve is not a process valve or pressure regulator and should not be misused as such. It should have to operate for one purpose only: overpressure protection.

Reasons for Excess Pressure in a Vessel

There are a number of reasons why the pressure in a vessel or system can exceed a predetermined limit. API Standard 521/ISO 23251 Sect. 4 provides a detailed guideline about causes of overpressure. The most common are:

- Blocked discharge

- Thermal expansion

- Chemical reaction

- Exposure to external fire, often referred to as “Fire Case”

Each of the above listed events may occur individually and separately from the other. They may also take place simultaneously. Each cause of overpressure also will create a different mass or volume flow to be discharged, e.g. small mass flow for thermal expansion and large mass flow in case of a chemical reaction. It is the user’s responsibility to determine a worst case scenario for the sizing and selection of a suitable pressure relief device.

Use case

Applications

-

Air service

-

Autoclaves

-

Chemical plants

-

Compressors

-

Continuous bypass duty

-

Pressure vessels

-

Receiver protection

-

Steam boilers

-

Steam service receivers

-

Variable backpressures

-

Storage vessels

-

Vessel protection

-

Steam thermal expansion relief

-

Steam processing equipment

-

Refineries

-

Pulp and paper mills

-

Pipeline protection

-

Pharmaceuticals

-

Heating & ventilation Industry

-

Heat exchangers

-

Food industry

Features

- Designed according to ASME Sec. VIII Div.1

- Sizing as per API 520

- Compliance to API 527 for Seat Leakage

- Blow down ring design as standard for adjustable blow down

- Diverse selection of high-alloy materials available as standard

- Longer lifetime due to hardened discs, Stellited seats

- Wide range of spring materials available to suit various process conditions

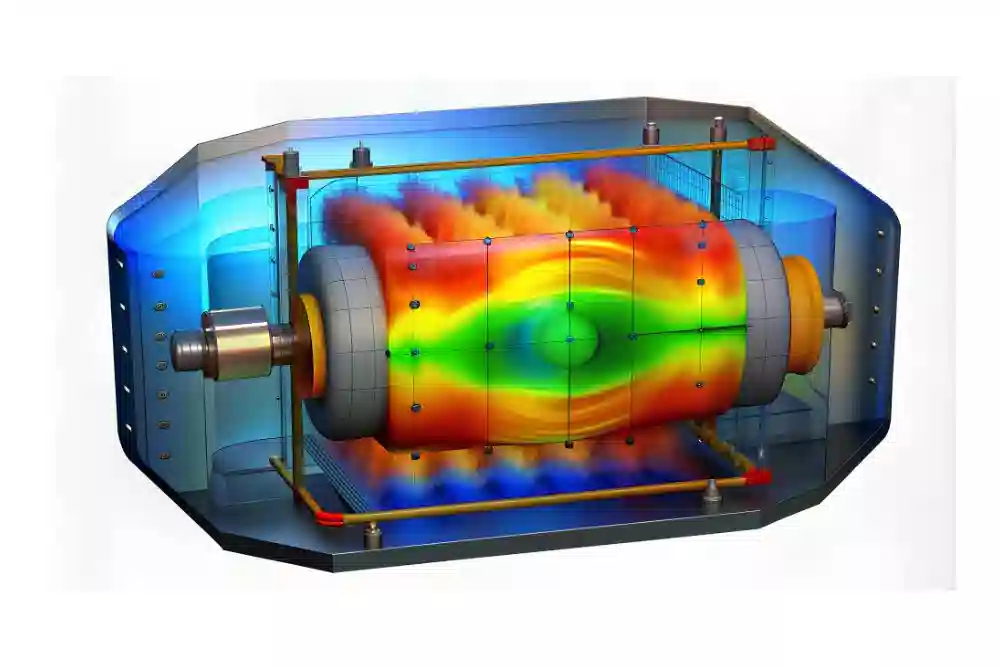

- Balanced bellow design available for effective performance variable back pressure conditions

- Certified test report verifying specified settings and leakage performance

- PESO approval available upon request

Specifications

- Sizes: 1”(DN 25) through 8” (DN 200)

- Sizes: ½”(DN 15) through 1”(DN 25)

- Orifice: from ‘D’ to ‘T’

- Flange Connections: ANSI as Std. (other flange std upon request)

- Set Range : from 0.15 – 100 bar

- Temperature Range: from -50 – 350 Deg C

- Materials: Carbon Steel, Stainless Steel, Hastelloy, Monel (other materials upon request)

- Teflon lined/coated option available upon request

Options

- Bellows, Lifting Lever, Test Gag available

- Soft Sealing option for Tight Shut off

- Sealing materials Viton, Neoprene, EPDM

- Non metallic Trim parts available for corrosive application

- Special Coatings: PTFE/PFA/Halar coating/Lining available

Let's start your project to be realize.

Our skilled team ensures that each valve meets stringent quality standards, offering durability and optimal performance. Explore our range of products and discover why we are a trusted name in valve manufacturing.