End-of-Line Pressure / Vacuum Relief Valve

- Home

- >

- End of line Pressure / Vacuum Relief Valve

Performance Driven

About the Product

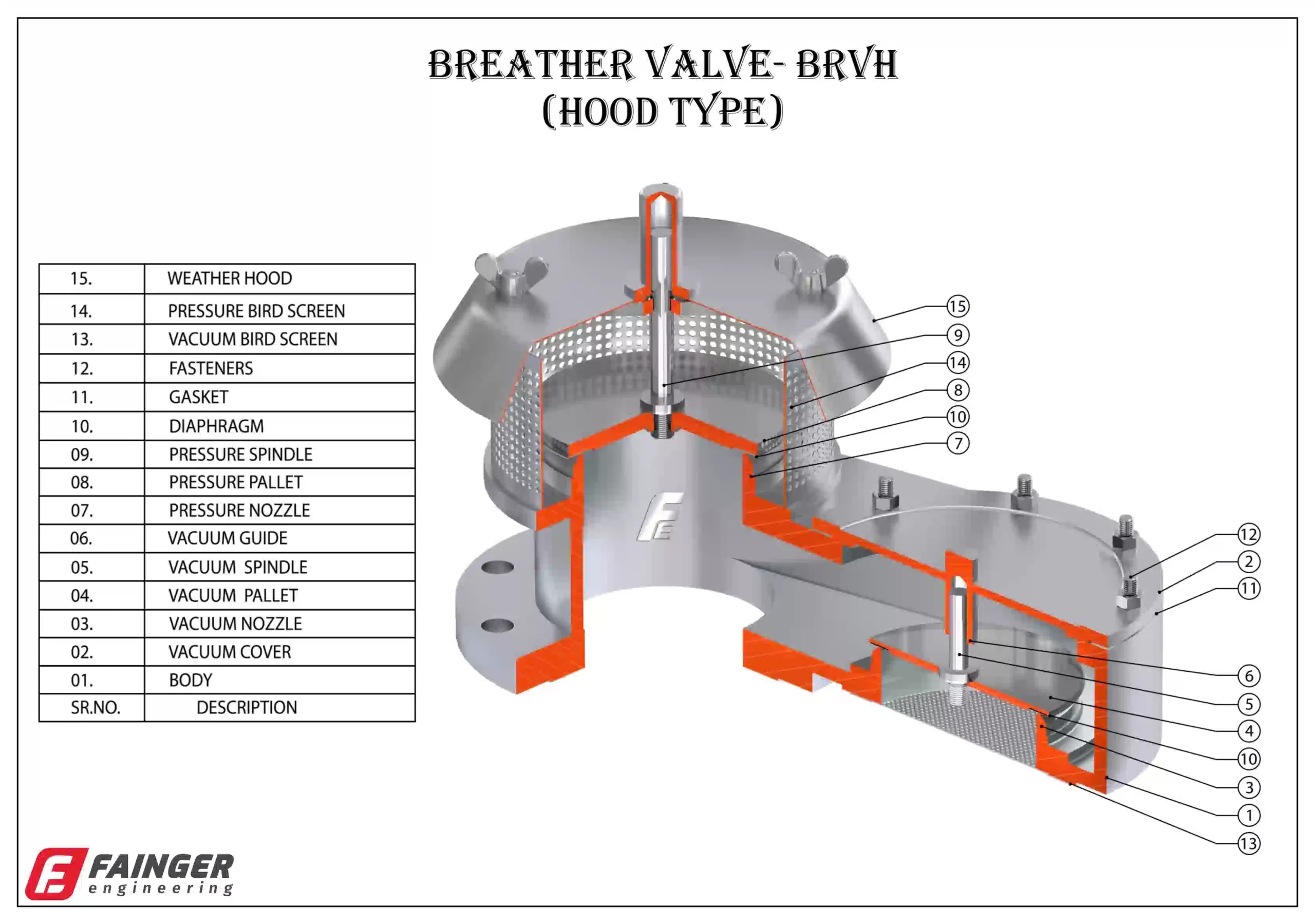

The Fainger make End of line Pressure /Vacuum Relief Valve (also known as Conservation Vent) are specially designed for tank protection and is intended to use where pressure & vacuum relief is required.

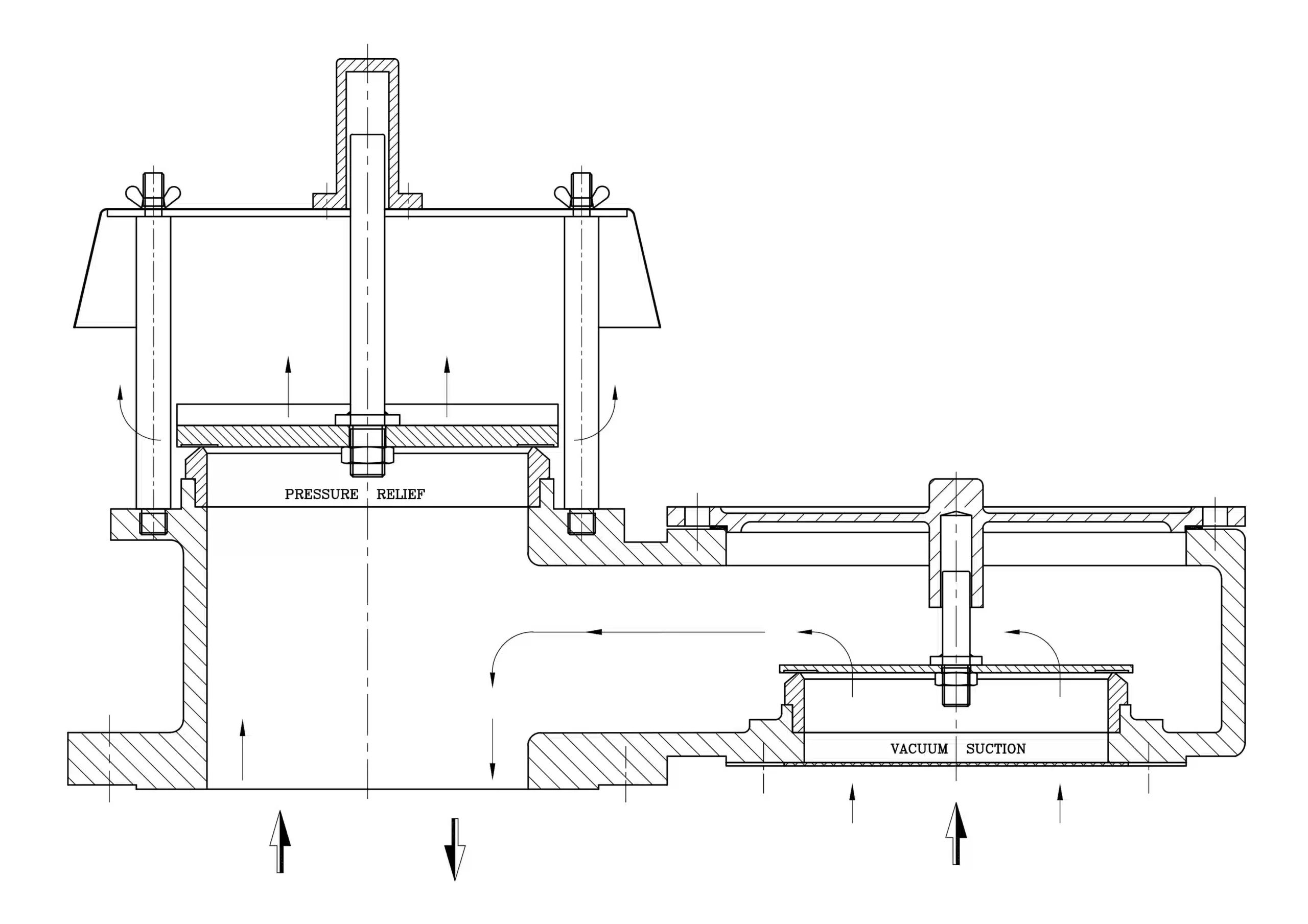

As the pressure builds in the tank, there is a differential created across the pressure relief Pallet. When this differential becomes great enough to lift the pallet; the pallet unseats / lifts and allows Vapor flow out of the tank.

The Pallet Re-Seats when the differential becomes low. Similarly, when vacuum is developed in the tank, the differential across the vacuum pallet eventually becomes great enough to lift the vacuum pallet and allows air to flow into the tank. The vacuum pallet re-seats when the differential is low.

Features

- Serialized unit for easy identification and traceability

- Easy inspection and easy maintenance

- Automatic condensate drainage design

- Pallet assembly guides and center pallet stem guide to ensure proper alignment of pallet assembly on the seat and smooth lifting and reseating action

- “Air-cushion” pallet design for better sealing and low leakage performance

- Designed and tested according to API 2000

Specifications

- Sizes: 1” (DN 50) through 14” (DN 350)

- Flange Connections: ANSI 150# as Standard (Other Flange Std available on request)

- Materials: Carbon Steel, Aluminium, Stainless Steel and Alloy C / C276. Non-metallic (PP-FRP) construction also available

- Standard Setting Range*: Pressure: 20 – 10000 mmWC

- Standard Setting Range*: Vacuum: 20 – 5000 mmWC

- * (Settings vary by size)

- Spring-loaded models available

Options

- Flange Connections: Alternate drilling patterns available upon request

- Diaphragm Materials: PTFE, Viton, Buna N, EPDM, Neoprene; other materials available upon request

- *Settings: Non-standard setting available

- Special Coatings: For corrosive service Teflon lining/coating, Halar coating available

- Material certifications for castings/Trim parts

- “Steam-Jacketing” available

Let's start your project to be realize.

Our skilled team ensures that each valve meets stringent quality standards, offering durability and optimal performance. Explore our range of products and discover why we are a trusted name in valve manufacturing.